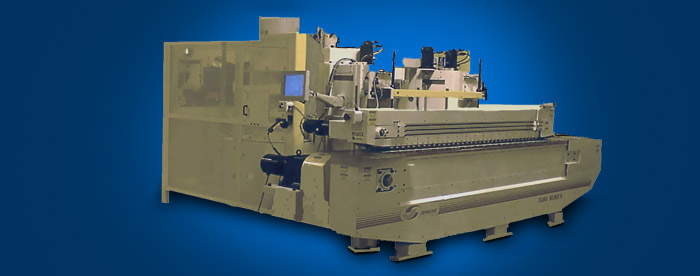

3200 Single End Machining Center

The 3200 series Single End has a robust frame and tool-stand design for the most demanding applications. The 3200 series machine provides the capacity and rigidity for many different configurations, allowing for maximum customization of your application.

Features

Feed Through Advantage

Feed through capabilities of this heavy-duty machine allows increased production. Whether it’s a simple manual shaping machine or a fully automated CNC controlled shape and sand, the machine can be customized for your specific application.

Heavy-Duty Base Feed Chain

Base components are constructed of heavy tubular steel weldment.

Feed Chain

The 3200 series feed chain is constructed of precision machined links to provide a highly accurate reference surface for cutting and blending applications. Feeding is accomplished by friction feeding on the rubber chain surface or with the included feed dogs.

Touch Screen Graphical Interface

Operator friendly software reduces operator training time and set-up changeover time, while ensuring setup accuracy. Maintenance monitoring, diagnostic reporting, trouble-shooting, online manual, production recording, part setup design and customized application software are all included.

Options

Automatic Lubrication

Fully customizable lubrication intervals make certain that all the bearings and ballnuts have adequate lubrication.

CNC Controlled Arching

Measure the part and cut the arch while the chain runs at a constant speed. Continuous Mode arching capability calculates arch shape geometry for a specific width based on only three parameters: arch height, shoulder length, and fillet radius. Family Mode programmable template matching capability produces parts that match components from other shapers and eliminates the need for cumbersome templates. Arch rails, panels and valances can be manufactured with ease.

Part Return System

Conveyor system returns parts to a single operator to complete machining on all sides.

Automatic Tool Changer

Possibilities from a simple 2-stack exchanger to 100-stack robotically controlled system to eliminate operator handling of tools are available.

Powered Holddown

Driven holddown runs at ±5% of the chain speed for friction feeding, dog feeding and feeding behind the dogs.

End Matching

Defecting and machining of random length hardwood flooring to tolerances of ±.003” or less.

Barcode Scanner

Automate your machine setup with a bar code scanner. This eliminates operator error and speeds the start of the setup process.